Technics

Impact resistance of robot safety fences

Work processes can also pose mechanical hazards, e.g. collisions of robots or parts of the tool or workpiece with the safety fence (for the causes, see article on restricted space). There is currently no normative…

Dimensions and fastening of robot safety fences

Robot safety fences ensure the safety of the working environment by preventing direct contact between the machines and the employees. You can find out some of the most important requirements here. Unfortunately, the technical requirements…

T2 mode no longer applicable as before

According to the present standards DIN EN ISO 10218-1:2012 and DIN EN ISO 10218-2:2012, three safety-related operating modes exist for industrial robots. Automatic, Manual at reduced speed (T1) and Manual at high speed (T2). Until…

Material entry and exit

In most cases industrial robot systems are equipped with interfaces for automatic material entry and exit. For this purpose, necessarily openings have to be provided at the perimeter safeguarding. Has the designer to consider that…

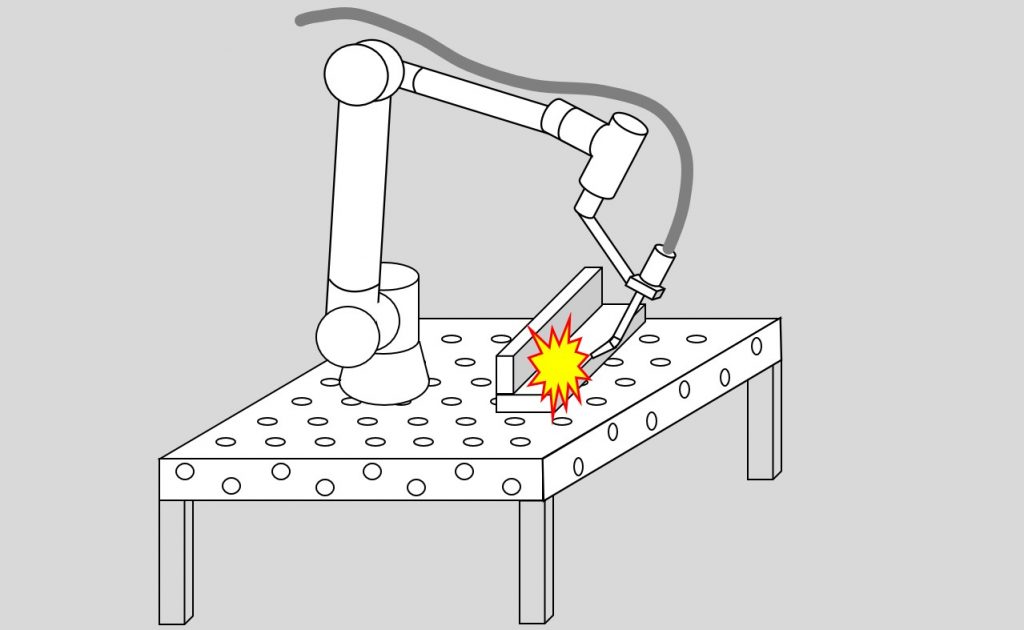

Cobots in welding technology

Cobots are considered flexible and inexpensive. This is why small and medium-sized companies like these machines. In many cases, cobot systems don’t even need a safety fence. But what about arc welding? We’ll show you…

Why Cobot projects can fail

Do you plan a cobot project? Then you should know what to do not ending in a deadlock. Unfortunately, sometimes companies are driving projects which will be no longer used after a short time. How…

Note: This webpage is a translation of German websites