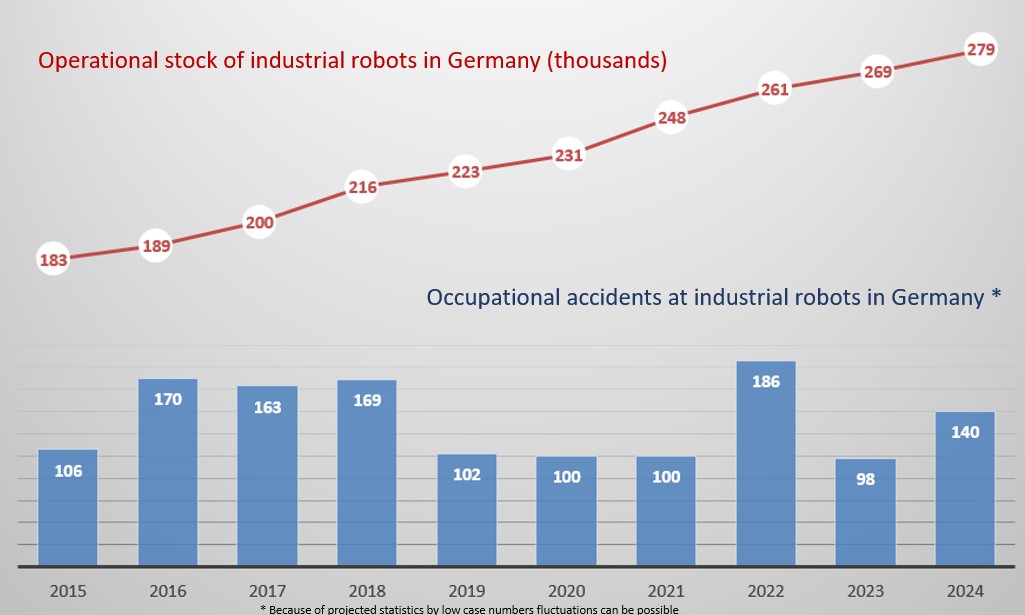

Despite the continuous increase in industrial robots in Germany, the number of occupational accidents involving industrial robots recorded by the German Occupational Accident Insurance (DGUV) remains at low level. In 2024, for example, 140 reportable* occupational accidents involving industrial robots occurred nationwide. In comparison, the total number of accidents in the area of accident insurance in the commercial sector and the public sector is 754,660 occupational accidents in the same period.

In addition, the stock of industrial robots in Germany continues to increase. According to the International Federation of Robotics ifr.org, the number of industrial robots in Germany increased from 183,000 to 279,000 between 2015 and 2024. Nevertheless, industrial robots also relieve employees of heavy or hazardous work. Another advantage for the use of robots is the removal of humans from the immediate process hazards. From the point of view of occupational safety, an interest in the use of robots should therefore also be justified.

| Occupational accidents 2024 | ||

| Total | Industrial robot | |

| Reportable occupational accidents | 754.660 | 140 |

| New occupational injury pensions (due to serious occupational accidents) | 9.923 | 3 |

| Fatal occupational accidents | 345 | 0 |

Table: Occupational accidents in Germany 2024, excerpt (source DGUV)

The table shown raises the question of whether the proportion of serious occupational accidents in the field of industrial robots is possibly higher than at other machines. However, this question can be answered No. Averaged over the years 2015-2023, the share of new occupational injury pensions in the accident rate for industrial robots is approximately 1.6%. This corresponds to roughly the same values as in the entire occupational accident situation or in the area of stationary machines. In the case of fatal occupational accidents, the proportion of 0.61% is even significantly lower than these comparative values.

However, the positive situation should not be a reason to rest.

According to the German Berufsgenossenschaft, more than three-quarters of all serious occupational accidents involving industrial robots occur during trouble shooting. Stuck parts or dirty sensors can lead to unexpected malfunctions or even downtime of the systems. Employees usually try to eliminate these disruptions as quickly as possible. As the DGUV reports, safeguards are sometimes bypassed. This exposes employees to a high level of risk.

The safety of industrial robot systems must therefore be further improved through technical, organizational and personal protective measures. The use of modern safeguards such as light curtains and laser scanners in conjunction with safety fences and safety-related controls offers employees a high level of protection. In addition, safety standards for industrial robots have been in place since the 1980s. If industrial robot systems are placed on the market in Europe, manufacturers are obliged to comply with the EC Machinery Directive. To specify the Machinery Directive, the EN ISO 10218-1 and EN ISO 10218-2 standards are listed in the Official Journal of the EU specifically for industrial robots. This means that robotics experts can draw on a comprehensive set of technical specifications..

* Work loss of more than 3 days

Note: This article is a translation of German websites